Plastic injection moulding

Development of new products, manufacture, and quality control

Lean organization gives us a lot of flexibility, which means that we can construct prototype tools or manufacture large batches of products very quickly. We provide comprehensive services, including tool construction, manufacturing, quality control, and product assembly.

Our seasoned experts will guide you step-by-step thought the process of obtaining your product. Thanks so their extensive know-how, we are able to tackle demanding technological challenges. In addition, we also provide services for the optimization of all company processes.

This process actively involves all our employees, which helps us to keep pace with market changes.

Comprehensive solutions

Development as a path to your success

Development partner

We will stand by you as partners throughout your development process. By keeping up with new developments, we can provide you with the opportunity to improve and make the best product possible. New ideas are contributed by all our employees, which allows for a rapid implementation of improvements in all project phases.

Product development

We develop products based on their technical and functional requirements. Knowledge of various solutions in the fields of thermoplastics and tool construction, enables for optimal tool development, and cost-effective and high-quality production.

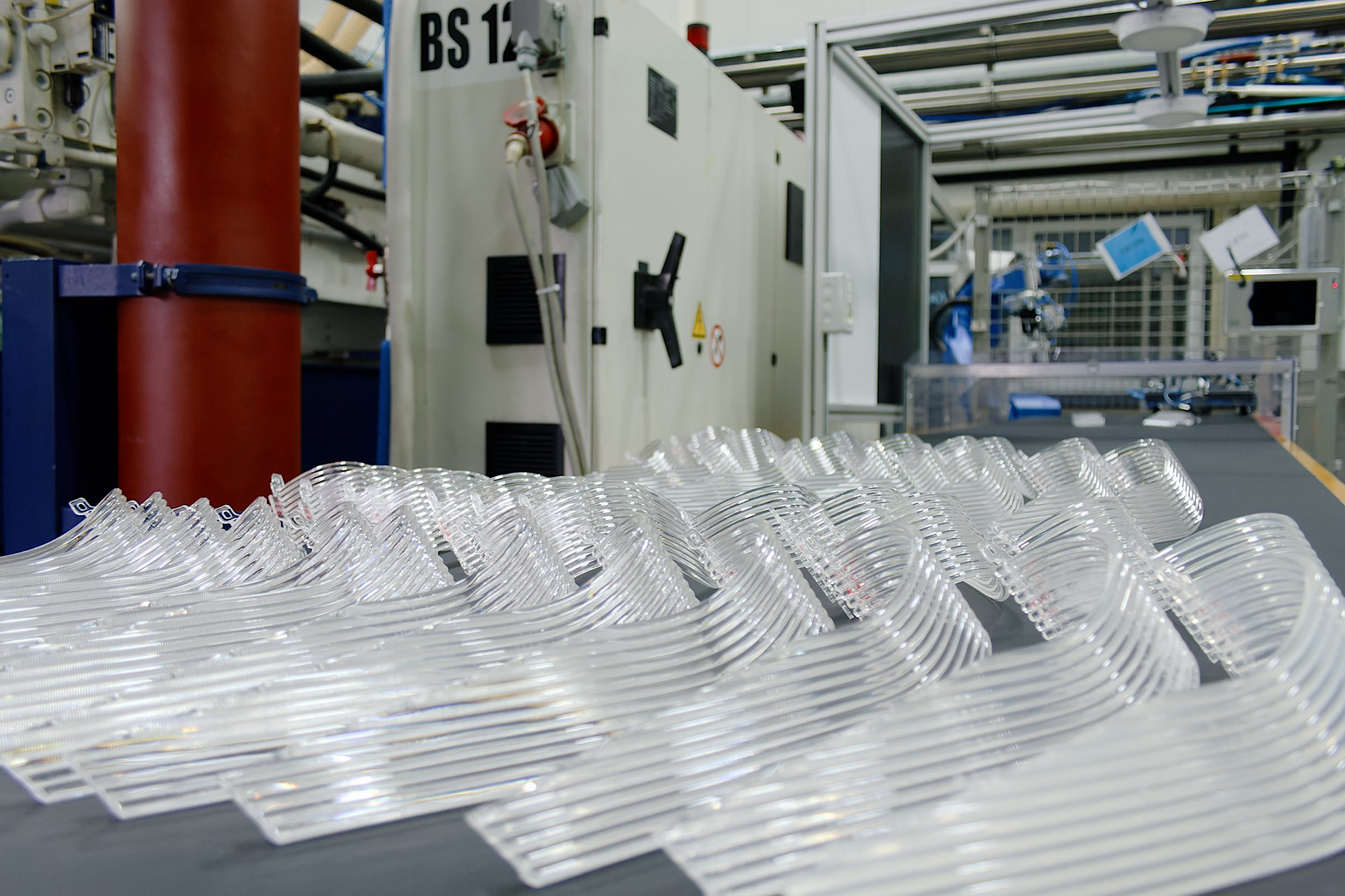

Manufacture of plastic products

We provide a complete service, starting from the idea and the prototype to tool construction, manufacturing, quality control, and product assembly. State of the art machinery, rapid development, experience, and a motivated team are our answer to all technological challenges. We provide injection moulding services for complex products made of various plastic materials. In addition, we can assemble products.

Our up-to-date organization structure provides for great flexibility. We can quickly produce prototype tools or large-series products and offer complete services, from the construction of tools, manufacturing, quality control and product assembly.

Our central drying system using hot dry air enables for a cleaner production and thus the highest quality of products, while the automatic dispense system allows for the granulate to reach the machines to be processed by in ideal conditions.

Quality management

2.850 ㎡

of production area

46

motivated employees

10 mio

products delivered per year

100.000

machine hours per year